In the ever-evolving landscape of manufacturing, the meticulous process of tooling and fixture design stands as the backbone for production efficiency and precision. At the forefront of this transformative journey is 3D Advantage Inc., a pioneering entity harnessing the power of 3D printing to redefine the standards of tool design.

The Evolution of Tool and Fixture Design

Traditional tooling and fixture design methods have long relied on conventional manufacturing techniques, often characterized by time-consuming processes and inherent design limitations.

However, the advent of 3D printing has injected a new level of innovation into this realm, offering unparalleled flexibility and efficiency.

Precision Redefined through 3D Printing

3D Advantage Inc. recognizes the intricate demands of modern manufacturing, where precision is non-negotiable. Leveraging cutting-edge 3D printing technology, the company has pioneered a paradigm shift in tool and fixture design.

The digital age demands more than traditional methods can deliver, and 3D Advantage Inc. rises to the occasion.

Unleashing the Power of Additive Manufacturing

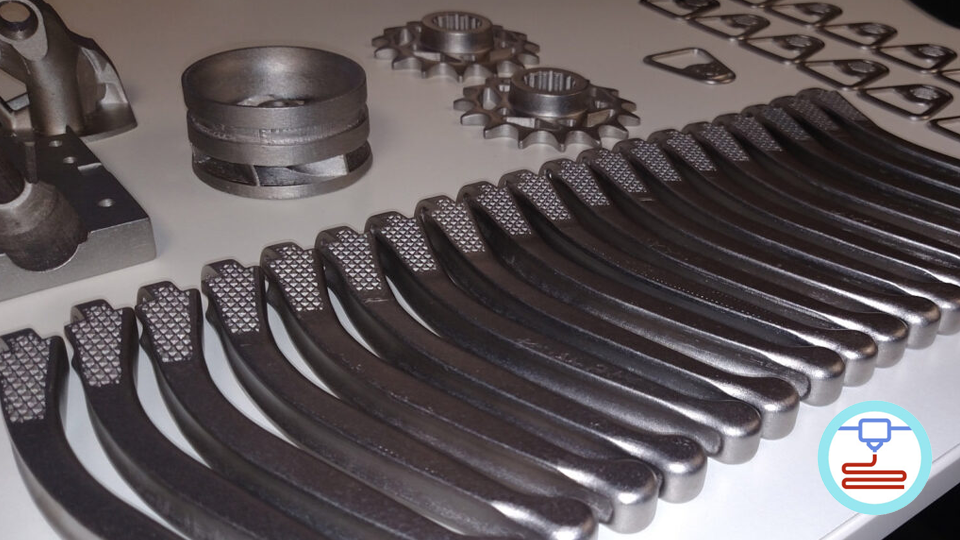

One of the major advantages that 3D printing brings to the table is the concept of additive manufacturing. Traditional subtractive methods often result in material wastage and limitations in design complexity.

With 3D printing, intricate and complex tooling and fixture designs are not just conceivable but also achievable with utmost precision.

Tailored Solutions for Varied Industries

3D Advantage Inc. prides itself on providing bespoke solutions for tool and fixture design across diverse industries. The inherent flexibility of 3D printing allows for the customization of tools and fixtures according to specific production requirements. This adaptability is a game-changer, especially in industries where unique and specialized designs are paramount.

Accelerating Prototyping and Iteration

In the fast-paced world of manufacturing, time is a critical factor. 3D Advantage Inc.’s commitment to efficiency is evident in the rapid prototyping capabilities facilitated by 3D printing.

Prototyping iterations are streamlined, allowing for quicker testing and refinement of fixture designs, ultimately reducing time-to-market for our clients.

Embracing the Future of Manufacturing

The role of 3D printing in tooling and fixture design cannot be overstated. 3D Advantage Inc. has established itself as a go-to solution where precision, customization, and efficiency converge seamlessly.

As manufacturing continues to evolve, embracing the transformative power of 3D printing is not only a choice but strategically vital for those aiming to stay at the forefront of the industry.

To fully explore the limitless possibilities of 3D printing in tooling and fixture design, contact us today and witness the future of manufacturing today.