More companies are 3D printing composites to make parts. Composite materials are utilized in additive manufacturing. A growing number of companies are integrating additive manufacturing technology everyday across all sectors and industries. Indeed, 3D printing has a wide range of applications, wider than we might believe at first glance. The 3D printing market is expected to be worth $1.73 billion in the next ten years.

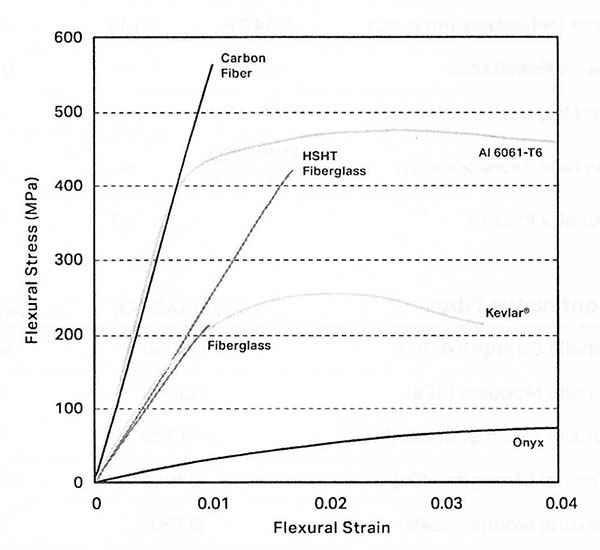

In general, even concrete could be considered a composite because it is a material made up of multiple different materials. However, the term is most often employed from an engineering point of view, which means we are talking about a material that has been reinforced with fibers. Even though fibers are very beneficial when combined with another material, they are almost never used by themselves to create a piece. Instead, they are added to a matrix material in the form of short fibers or in the form of continuous fiber reinforcement. One of the most popular fibers in the 3D printing industry is carbon fiber because it has one of the highest strength-to-weight ratios.

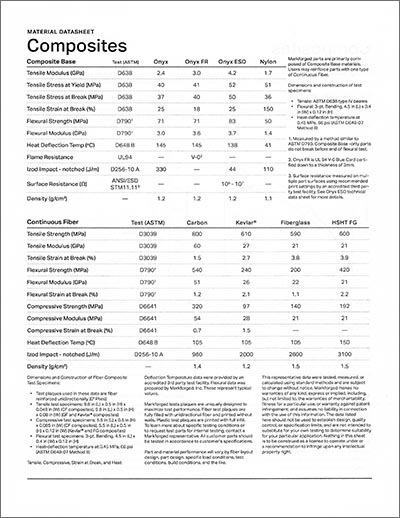

Composites

Our printers are capable of Continuous Fiber Reinforcement (CFR). A process that reinforces FFF parts with high-strength continuous fibers. A CFR capable machine uses two extrusion systems: one that extrudes Composite Base material in a standard FFF process, and a second for long strand continuous fibers that are laid down in-layer, replacing FFF infill.

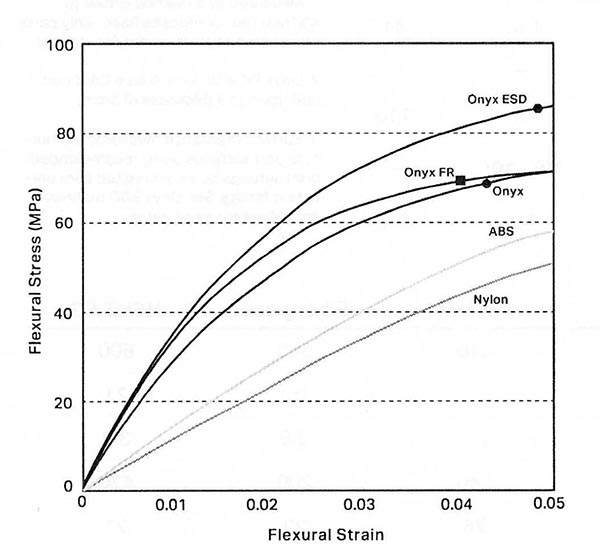

Composite Base

Our composite base materials print like conventional FFF thermoplastics. They can be printed by themselves, or reinforced with any of our continuous fibers, including Carbon Fiber, Kevlar, and Fiberglass.

Continuous Fiber

Continuous Fibers are laid down on the inside of parts through a second fiber nozzle They cannot be printed by themselves — instead, they are used to reinforce parts out of a composite base material like Onyx.