3D Advantage, Inc. is a boutique industrial metal and plastic additive manufacturing operation located in Doylestown, Pennsylvania.

Additive Manufacturing

We utilize a transformative method of industrial production called additive manufacturing that enables the fashioning of lighter, stronger parts and systems. One of the greatest advantages of additive manufacturing is the swift turnaround time – you are only days away from receiving a finished design. 3D Advantage also prides itself on individualizing each customer experience to meet your needs.

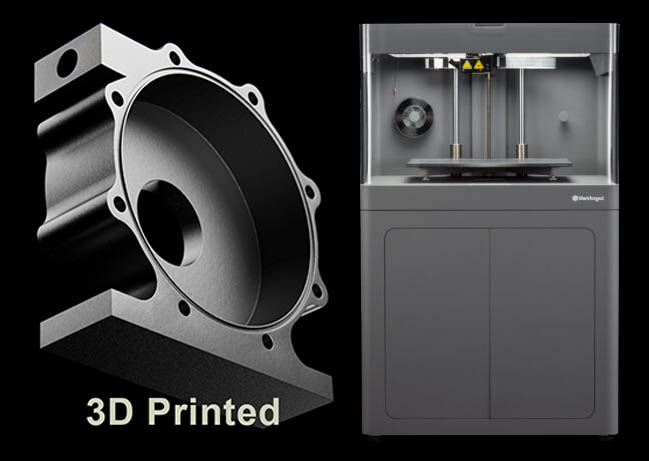

Our Fastest and biggest 3d printer: The FX20

We have added the FX20, from MarkedForge© with a build volume of 525 × 400 × 400 mm. The fused filament fabrication (FFF) machine is equipped with a heated print bed that can reach 200˚C, enabling it to handle high temperature materials such as Ultem, as well as continuous fibers for added strength.

The FX20 is capable of printing flame-retardant, high-performance thermoplastic with ULTEM 9085 filament and Markforged’s proprietary Continuous Fiber Reinforcement technology. This new hardware and printing material will make it possible to produce parts for the aerospace, automotive and oil and gas industries where high performance and the ability to withstand high temperatures is essential.

3D Printed Replacement Parts

If you have a broken part you need replaced but can no longer find it available from the original equipment manufacturer. Contact us.

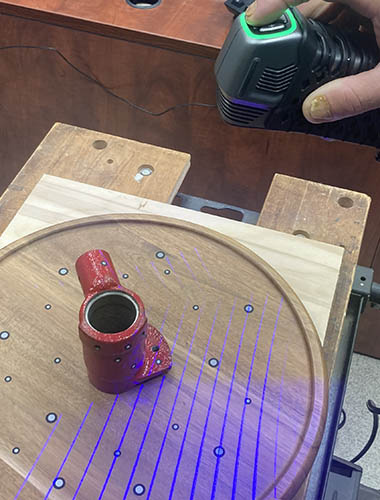

Replacement Part Scanning

By using a Scan Tech scanner, it’s possible to scan objects in high detail to create a 3D model known as an “object mesh file.” The hand-held scanning device uses advanced technology to capture the shape and surfaces of the object and convert it into a digital format.

The resulting object mesh can be used for a variety of purposes such as 3D printing. With the Scan Tech device, creating a 3D model of an object is a fast and efficient process that can save time and effort compared to traditional methods. MORE INFORMATION>